Rack It Right

Inspection Levels

Inspection Levels

-

✔ Improve workplace safety

✔ Improve workplace safety

✔ Lower liability in the event of an accident

✔ Comply with current safety standards

✔ Increase lifespan of your rack systems

✔ Improve employee retention & morale

-

Level 1 - Rack Damage Inspection

Accidental damage to rack structures by powered fork lift equipment cannot be overlooked. Let our team of experienced inspectors perform a thorough ground-level or aerial inspection of your storage system to identify damaged components. A clear, written report and detailed drawing will highlight all the components requiring your attention so that a proper action plan can be quickly implemented. -

Level 2 - Routine Rack Inspection

Maintaining your storage system requires regular inspections. As per the CSA A344-17, competent personnel should perform monthly routine rack inspections to identify and document out-of-position components, damage and poor operating practices. Let our experienced inspectors take the load off you. Our detailed reports and drawing will identify and categorize all tagged rack deficiencies. -

Level 3 - Expert Rack Inspection

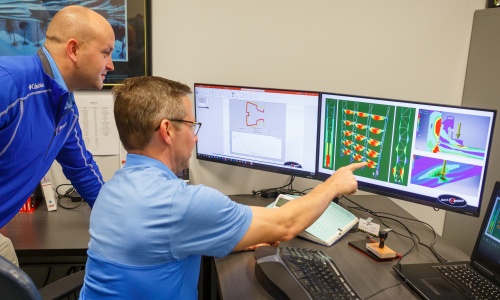

Assessing rack damage and other deficiencies is a complex task. As per the CSA A344-17, an expert rack inspection should be conducted by specialized personnel on a yearly basis. Our expert inspections are performed with the use of digital measuring tools and are supervised by professional engineers. Detailed reports include rack damage limits and provide time guidelines for specified corrective action. -

Level 4 - Rack Capacity Inspection

No drawings of your storage system? Not sure of its rated capacity? We can help. Our team of licenced professional engineers, experienced in rack design, will review your existing storage system and perform a rigorous analysis using advanced techniques. An engineering report and drawing will outline the load capacity for each rack configuration and advise on compliance to current standards.